Selecting the right light duty racking system is crucial for optimizing storage space, ensuring safety, and enhancing operational efficiency. Light duty racking systems are designed for storing lighter items and are commonly used in various settings, including warehouses, retail stores, offices, and even homes. This guide will help you navigate the key factors to consider when choosing the appropriate light duty racking system for your specific needs.

Understanding Light Duty Racking Systems

Light duty racking systems are storage solutions designed to hold lighter loads. These systems are versatile, easy to assemble, and can be customized to fit different spaces and storage requirements. They are ideal for environments where heavy-duty racking is unnecessary, such as small warehouses, retail backrooms, and home garages.

Key Factors to Consider

1. Load Capacity

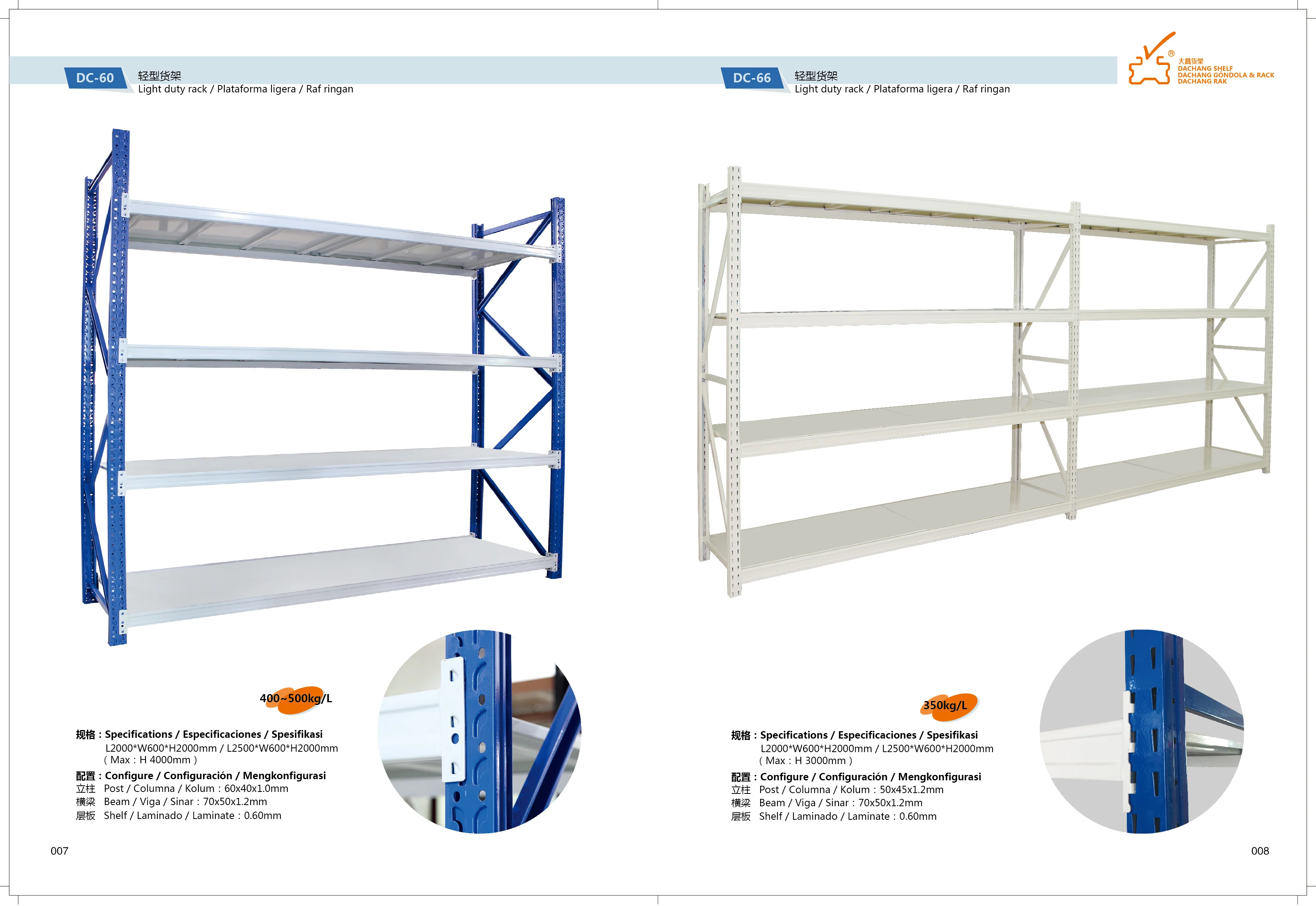

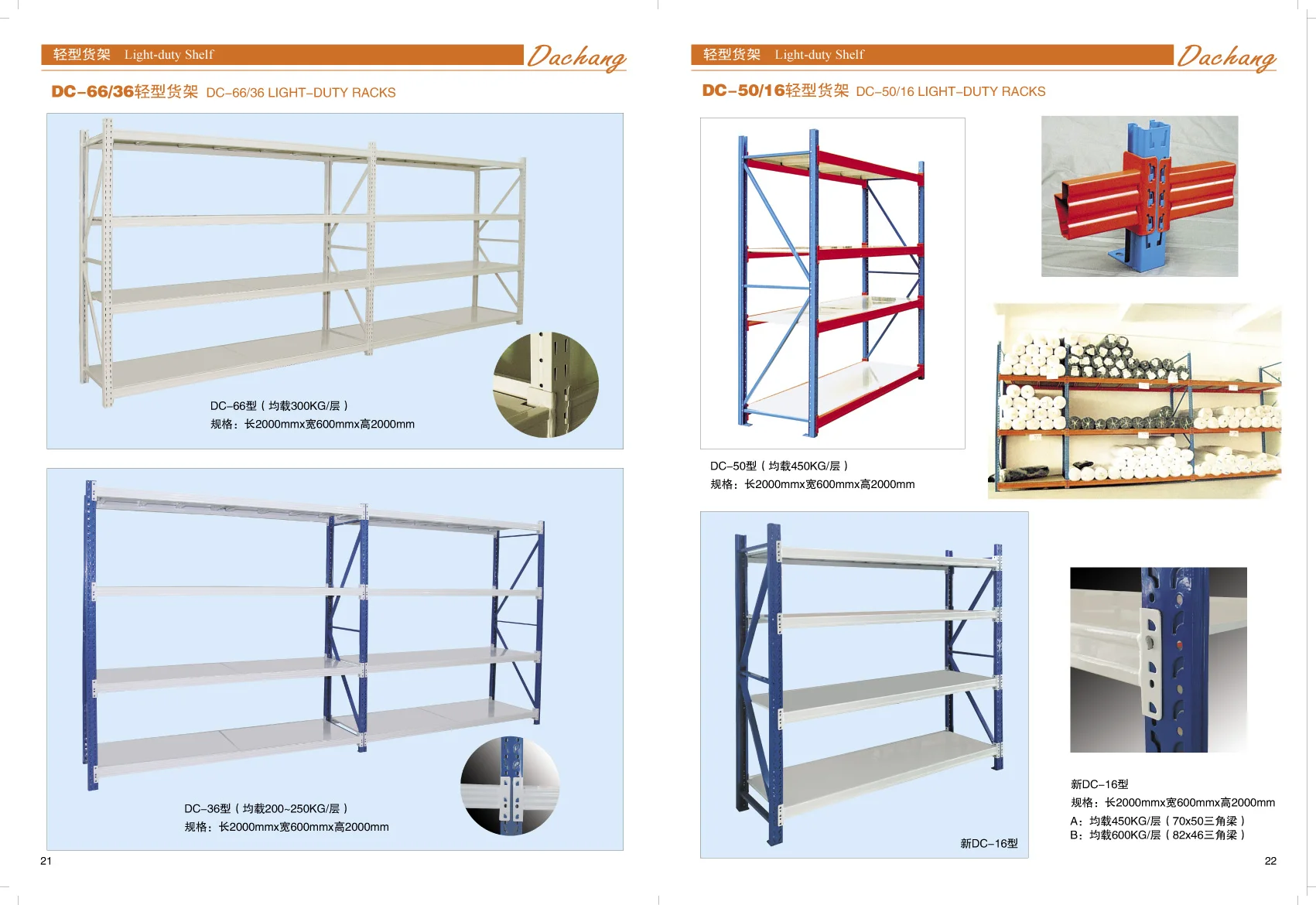

The load capacity of a racking system is one of the most critical factors to consider. Light duty racking systems are designed to handle lighter loads, but it's essential to ensure that the system you choose can support the weight of the items you plan to store.

Hand-Loaded Items: If your items can be hand-loaded and weigh no more than 20 kg each, a light duty boltless rack system with a capacity of up to 200 kg per tier will suffice.

Medium Weight Items: For items weighing between 20 kg and 80 kg, consider medium duty racking systems, which can support up to 500 kg per tier.

2. Material and Construction

The material and construction of the racking system affect its durability, stability, and suitability for different environments.

Steel Racks: Most light duty racking systems are made from cold-rolled steel, which offers strength and durability. These racks often feature a powder-coated finish to prevent rust and corrosion.

Galvanized Racks: For environments where moisture is a concern, galvanized racks are a good option as they are resistant to rust and corrosion.

3. Ease of Assembly and Adjustability

Light duty racking systems should be easy to assemble and adjust to accommodate changing storage needs.

Boltless Racks: These racks are popular due to their ease of assembly. They use connector hooks and catches instead of bolts, making them quick to set up and adjust.

Adjustable Shelves: Look for racking systems with adjustable shelves, allowing you to change the height of each tier to fit different items.

4. Space Utilization

Maximizing space utilization is essential for efficient storage. Consider the following:

Aisle Width: Ensure that the aisle width in your storage area is sufficient for easy access to items. For light duty racking systems, an aisle width of 80 to 120 cm is recommended.

Vertical Space: Utilize vertical space by choosing racking systems that can be stacked higher. Light duty racks can typically be adjusted in height to make the most of available space.

5. Specific Storage Requirements

Different environments have unique storage needs. Here are some considerations based on specific requirements:

Retail Stores: Light duty racking systems are ideal for organizing consumer products like electronics, apparel, and cosmetics. They provide easy access and help maintain an organized storage area.

Pharmaceutical and Healthcare Facilities: These environments require precision and accessibility for storing medications and medical supplies. Light duty racks with high accessibility and precise inventory organization are suitable.

Home and Garage Storage: For home use, light duty racking systems can efficiently organize garages and craft rooms. They are perfect for storing small, lightweight items.

Types of Light Duty Racking Systems

There are various types of light duty racking systems, each suited for different applications:

Boltless Racks: These are easy to assemble and adjust, making them ideal for dynamic storage needs.

Slotted Angle Racks: These racks are made from high-quality cold-rolled steel and are easy to disassemble and adjust. They are suitable for storing light and medium-sized items.

Cantilever Racks: These are used for storing long, bulky items like pipes and lumber. They are available in light duty versions for lighter loads.

Safety Considerations

Safety is paramount when choosing and using racking systems. Here are some safety tips:

Regular Inspections: Conduct regular inspections to check for any damage or wear and tear. This helps prevent accidents and ensures the longevity of the racking system.

Weight Limits: Always adhere to the weight limits specified by the manufacturer to avoid overloading the racks.

Proper Training: Ensure that employees are trained on how to load and unload items safely and how to report any damage or instability in the racking system.

Conclusion

Whether for a warehouse, retail store, or home garage, the right light duty racking system can significantly improve your storage organization and operational productivity. Choosing the right light duty racking system involves considering load capacity, material, ease of assembly, space utilization, and specific storage requirements. By carefully evaluating these factors, you can select a racking system that enhances your storage efficiency, ensures safety, and meets your unique needs.

.jpg)