Light duty racking systems are essential storage solutions designed to efficiently organize and store lightweight items in various settings. This guide will cover the basics of light duty racking systems, including their structure, materials, common uses, and benefits.

Structure and Materials

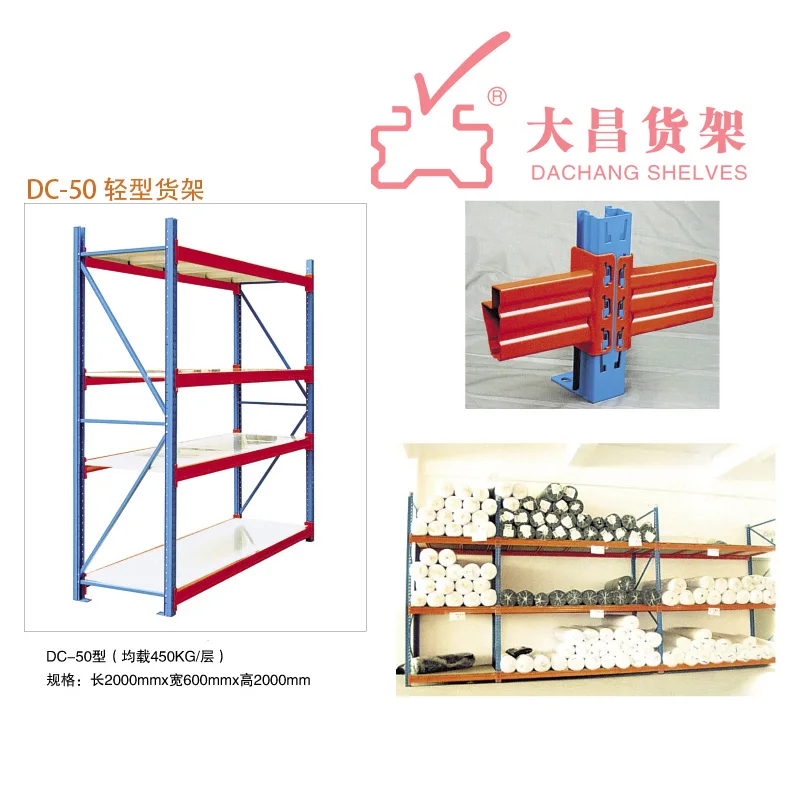

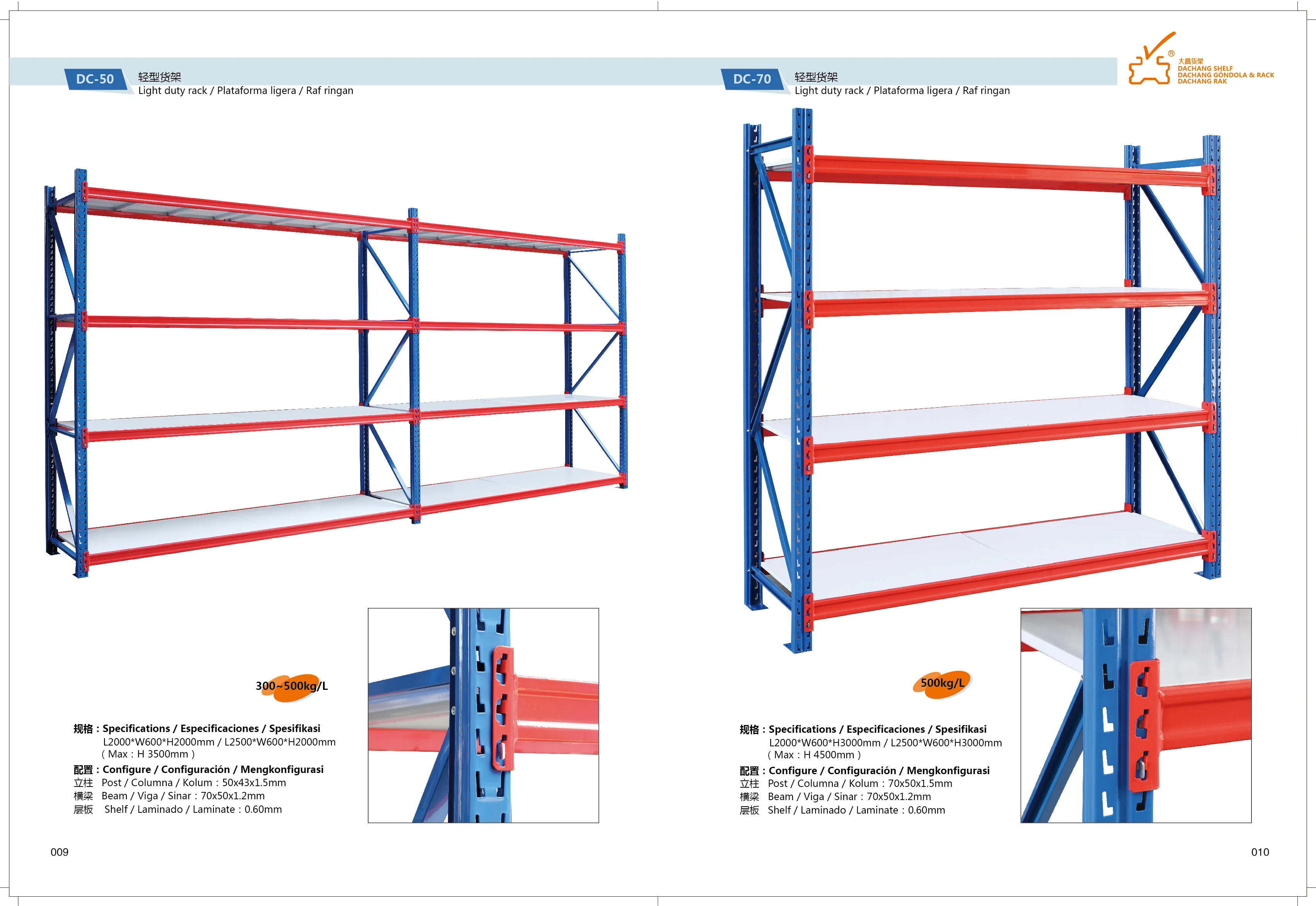

Structure: Light duty racking systems are typically composed of three main components: steel columns, beams, and decking. These systems are fully assembled structures that can be easily combined, installed, and disassembled, offering flexibility and convenience. The racks often feature adjustable shelves, allowing users to modify the height and spacing according to their storage needs.

Materials: Most light duty racking systems are made from high-quality materials such as steel or aluminum, which provide durability and resistance to wear and tear. The surface treatment of these racks often includes polishing, rust removal, oil removal, and electrostatic powder spraying, which enhances their appearance and longevity. Some systems also use cold-rolled steel plates, which are flattened, slit, bent, and welded to form reinforcing ribs, ensuring stability and strength.

Benefits of Using Light Duty Racking Systems

Light duty racking systems offer numerous benefits, making them a popular choice for businesses and individuals:

Versatility: These systems can be customized to fit a wide range of storage needs, from small items to larger, lightweight goods.

Ease of Installation: Light duty racking systems can be easily assembled with basic tools, making them a cost-effective option for businesses looking to save on installation costs.

Durability: Made from high-quality materials, these racks can withstand heavy use and resist damage from impacts and other types of wear and tear.

Space Optimization: The three-dimensional structure of light duty racks allows for full utilization of warehouse space, improving storage capacity and organization.

Cost-Effective: Light duty racking systems are generally more affordable than heavy-duty alternatives, making them an economical choice for many businesses.

Safety and Maintenance: These racks can be equipped with moisture-proof, dust-proof, anti-theft, and anti-damage measures, ensuring the safety and quality of stored goods. Regular cleaning and proper placement can extend the service life of the racks.

Applications in Various Industries

Light duty racking systems are versatile and can be used in various industries and settings, including:

Retail Stores: Ideal for displaying and storing small, lightweight items such as clothing, shoes, and electronics.

Offices: Useful for organizing files, documents, and office supplies, making them easily accessible.

Garages and Workshops: Suitable for storing vehicle parts, tools, and paints.

E-commerce Warehouses: Perfect for housing various product categories in e-commerce operations.

Pharmaceutical and Healthcare Facilities: Utilized for storing medications and medical supplies with precision and accessibility.

Craft and Hobby Stores: Efficient for organizing crafting materials and small tools.

Light duty racking systems are an invaluable tool for optimizing storage solutions in various settings. Their versatility, ease of installation, durability, and cost-effectiveness make them a preferred choice for businesses looking to improve their warehouse organization and efficiency. Whether used in retail stores, offices, garages, or industrial warehouses, light duty racking systems provide a reliable and efficient way to manage and store lightweight items.

By understanding the structure, materials, common uses, and benefits of light duty racking systems, businesses can make informed decisions to enhance their storage capabilities and overall operational efficiency.

.jpg)